Vacuum Conveying System Manufacturers in India – Rathi Engineering

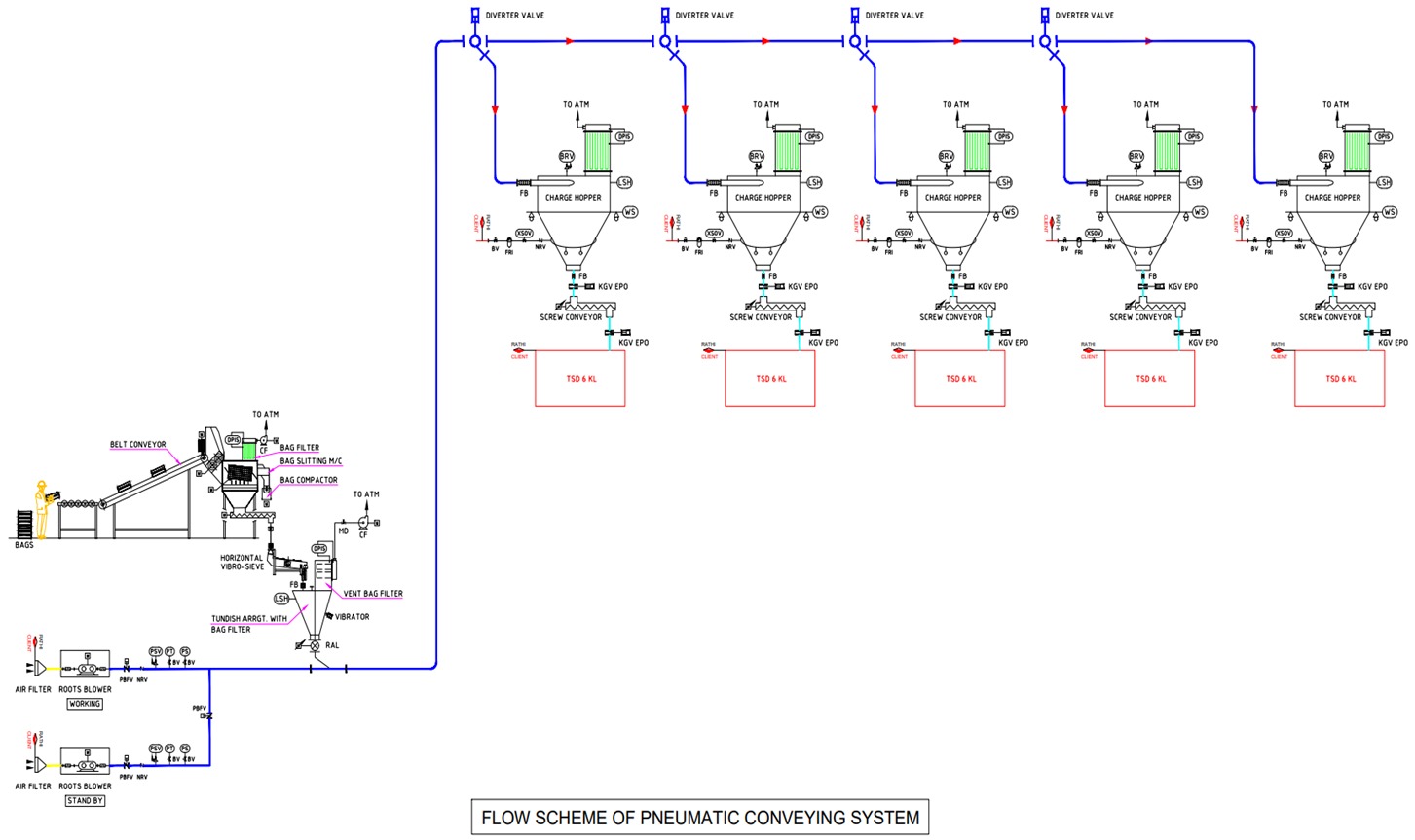

Rathi Engineering is one of the top vacuum conveying systems manufacturers, suppliers and exporters in India. We are providing the best vacuum conveying machine, which is used for moving dry materials such as dry materials, powders, granules and flakes from one location to another location within a factory or industrial production line with the help of suction.

These are made with strong-quality materials such as stainless steel, cast iron and aluminum for finishing. We have used a new technological sensor in our vacuum conveying system for live tracking of multiple processes. Let’s check its multiple types, benefits and applications one by one!

Our multiple types of Vacuum Conveying System Manufacturers:

Being one of the best vacuum conveying system suppliers and exporters in India, we are providing multiple types of vacuum conveying systems for increasing performance in multiple applications. Here we have listed down some types, such as:

- Dilute Phase Vacuum Conveying: These systems are used in large-scale manufacturing processes, particularly in the food and pharmaceutical industries. In a dilute-phase system, materials are conveyed in a suspension from a high-velocity air stream. With the help of higher pressure, the material travels at high speed through the pipeline. To improve the flow rate, we have implemented variable frequency drives (VFDs) for accurate flow control, and pipes have been upgraded with low-friction coatings for smoother material flow.

- Dense Phase Vacuum Conveying: This system is designed for handling bulk materials and transporting them at lower velocities. The materials are transported in a more compact and slug-like manner. To ensure smooth control of the system, we have integrated automated pressure adjustment systems to maintain the right balance of material flow and air pressure. Smart sensors are also employed to monitor flow patterns and prevent blockages, making this system ideal for fragile materials like coffee beans and grains.

- Central Vacuum Conveying System: This type of system transports and picks up materials from one or more destinations and is commonly used in large-scale industries such as packaging, automotive, and food processing. With the integration of Industry 4.0 technologies, these centralized control systems monitor and optimize the overall pressure rate of the conveying system. Our modern central vacuum conveying system can now be operated remotely.

- Vacuum Receiver System: This vacuum system uses a pump connected to a receiver that separates conveyed materials from the conveying air. The receiver is located at a higher point or above the destination, such as a hopper or mixer. To enhance the overall quality and performance of the system, we have installed a new dust filtration system that keeps the system hygienic and prevents blockages.

Technical Specifications of our Vacuum Conveying System:

For more information about our vacuum conveying system, we have mentioned below a technical sheet where it simply classifies each technical point:

| Specification | Dilute Phase Vacuum Conveying | Dense Phase Vacuum Conveying | Central Vacuum Conveying System | Vacuum Receiver System |

|---|---|---|---|---|

| Conveying Velocity | High (15–30 m/s) | Low (2–10 m/s) | Moderate (10–20 m/s) | Variable, depending on material and distance |

| Material-to-Air Ratio | Low (More air, less material) | Low (More air, less material) | Low (More air, less material) | Low (More air, less material) |

| Vacuum Level | 300–500 mbar | 600–900 mbar | 400–600 mbar | 400–700 mbar |

| System Capacity | High throughput (Large volumes, longer distances) | Medium to high throughput (Shorter distances but higher material load) | Medium to large capacity for multiple points | Medium to high capacity for batch processing and direct feeding |

| Air Pressure Requirement | 0.2–0.5 bar | 0.6–1.0 bar | 0.5–0.7 bar | 0.4–0.8 bar |

| Conveying Distance | Long distances (up to 100 meters or more) | Short to moderate distances (up to 50 meters) | Long distances with multi-point access (up to 200 meters in some cases) | Short to moderate distances (up to 50 meters, often within a plant) |

| System Capacity | Moderate to large flow rates, typically up to 10,000 kg/h. | Lower flow rates but high material concentration, typically 2,000–4,000 kg/h. | Varies significantly based on system design, but typically handles large material flows (up to 20,000 kg/h). | Typically optimized for batch processing, 100 kg/h to 5,000 kg/h, depending on application. |

Some unique technological features and new benefits of our vacuum conveying system:

One of the best vacuum conveying system suppliers and exporters in India, we have included multiple types of features that support increasing productivity in every industry. Here we have mentioned some points, such as:

- Regenerative Blowers: This technology is commonly employed in vacuum conveying systems and pneumatic conveying applications. Regenerative blowers save energy by recovering it from continuous airflow. They direct air through a series of internal vanes or impellers, allowing for energy savings by repeatedly passing air throughout the system. This efficiency reduces operational costs.

- Smart Control Systems: Our vacuum conveying systems are equipped with multiple sensors that provide real-time monitoring of every process. These sensors utilize intelligent algorithms to continuously monitor vacuum levels, flow rates, and material feed rates. This smooth operation allows for the early detection of issues, increasing performance and reducing maintenance requirements.

- Self-Cleaning Filters: To minimize human labor and save time, we have incorporated self-cleaning technology in our vacuum conveying systems. This technology uses minimal water along with advanced pumps and automated cleaning mechanisms to clean the filtration system after each task. This enhances hygiene and ensures consistent performance.

- Direct-Change Loading: These systems are specifically designed for industrial applications, enabling the direct transfer of materials into processing equipment such as blenders, mixers, and presses. This feature reduces manual handling of materials from storage or transport. Typically used in the food and beverage industries and pharmaceuticals, it facilitates the careful handling of bulk materials from a source to a blending vessel.

Applications of our Vacuum Conveying System:

Being one of the best vacuum conveying system suppliers and exporters in India, all our systems are made with advanced technological systems that give higher performance in every industry, such as:

- Transporting pharmaceutical powders and granules efficiently

- Moving fragile food products in production lines

- Conveying bulk chemicals in closed systems safely

- Automating plastic resin and pellet transport systems

- Handling sensitive electronic components with precision

- Transferring coffee beans to food processing plants

- Conveying metal powders in additive manufacturing

- Moving fine powders in the cosmetics manufacturing process

- Transferring capsules and tablets to pharmaceutical lines

- Automating spice transfer in food production facilities

As former vacuum conveying system manufacturers, suppliers and exporters in India, we, Rathi Engineering, are providing one of the best vacuum conveying systems, which are made with new technological updates and pure quality materials. Our all types are highly versatile and can be applied in numerous industrial sectors due to their advanced technological features. Contact us today for more information!