At Rathi Engineering Solutions, we design and manufacture custom

Besan Grinding Plants to meet the unique needs of the food processing

industry. Our team of experienced engineers and technicians work closely

with clients to design and develop a bespoke grinding solution that is

tailored to their specific requirements.

Our Besan Grinding Plants are designed to provide efficient and reliable

performance, ensuring maximum productivity and minimum downtime. We offer a

range of services, including:

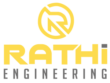

- Design and Engineering: Our team of experts will work closely with you to understand your requirements and create a customized solution that meets your needs. We use the latest CAD tools and software to create 3D models and simulations, ensuring that the final product meets all specifications.

- Manufacturing: Our state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, allowing us to produce high-quality Besan Grinding Plants. Our manufacturing process follows strict quality standards, ensuring that every product that leaves our facility is of the highest quality.

- Installation and Commissioning: Our team of technicians provides complete installation and commissioning services for all our Besan Grinding Plants. We ensure that the installation is carried out efficiently and that the equipment is up and running as quickly as possible.

- Maintenance and Support: We offer comprehensive maintenance and support services to ensure that your Besan Grinding Plant remains in top condition. Our team of experts provides regular maintenance checks and can quickly diagnose and repair any issues that arise.

- Minimum Moisture Loss

- Optimised Power consumption

- Reduced Noise level

- Dust Free Operation

- Machine can be easily cleaned with air.

- Easy Door Opening arrangement

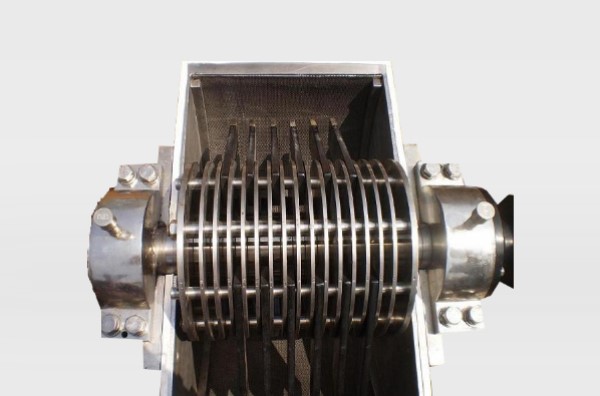

- Material to be ground is conveyed from the hopper by the variable speed screw feed or rotary airlock valve into the grinding chamber.

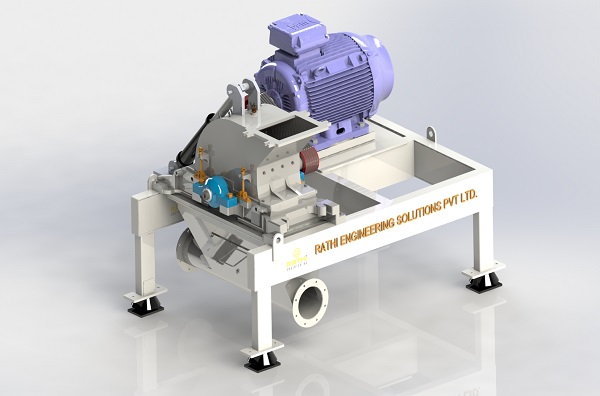

- The grinding occurs when product meets rotating disc along with the hammers and Multiple Deflector liner.

- The reduced or fine particles passing through VFD adjustable air classifier wheel are carried upward by the air flow with the help of centrifugal fan.

- Product is collected from High efficiency Pulsaire Jet Product Collector through the below rotary air lock valve.

- Over size particles are carried downward by internal circulating air stream and returned to impact rotor for regrinding.

- Rathi Engineering made air classifier mill is equipped with protection device for safety operation. A safety switch mounted on the cover of the grinding chamber checks if the mill door is open and if yes then all drives motor cannot run until mill door is closed.

Output Capacities

| Machine, Model | Capacity (Kg/hr) |

|---|---|

| ACM10 ACM30 ACM60 ACM100 ACM120 ACM150 ACM200 |

120-160 300-500 600-1000 1200-1500 1300-1900 1700-2200 2400-3000 |

- Air Classifying Mill

- Centrifugal Fan

- Rotary Airlock valve

- Vibro sifter

Industries

Cement

Agro Chemicals

Chemicals

Minerals

Paints

Pharmaceutical

Steel