Rathi Top Pneumatic Conveying System Manufacturers in India - Rathi Engineering

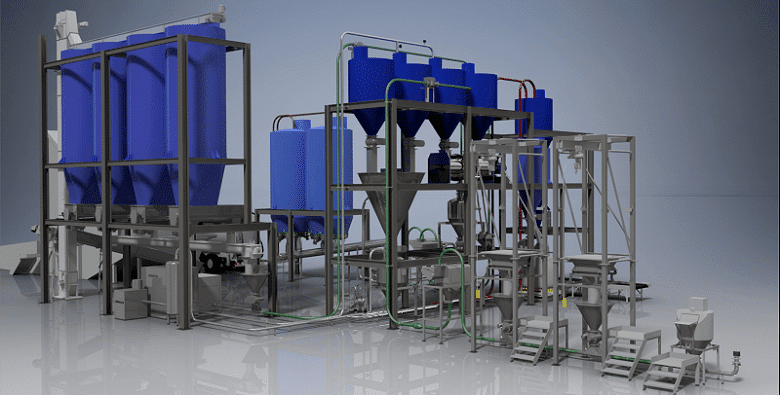

Rathi Engineering is a former pneumatic conveying system manufacturers in India, suppliers and exporters in India. These pneumatic systems are commonly used in industries including food, chemical, pharmaceutical and nutraceutical for moving solid, granular or dusty materials through pipelines using compressed air or gas.

These are used for a variety of functions, such as loading and unloading industrial machinery or containers. In food or chemical industries, these are used to distribute powders at multiple points of discharge and dust separation. We have added multiple types of technologies in these pneumatic conveying systems to increase the performance.

Our Multiple Types of Pneumatic Conveying System Manufacturers, which we offer:

Being one of the top pneumatic conveying systems suppliers and exporters in India, we are providing multiple types of systems

- Dilute Phase Conveying System: This system suspends materials in a high-velocity airstream at relatively low pressure. It is suitable for lightweight and abrasive materials. Recent technological updates include smart monitoring systems and advanced dust filtration, where connected sensors enable live monitoring and effective dust removal.

- Dense Phase Conveying System: Designed for handling abrasive, fragile, or cohesive materials, this system operates under low velocities and high pressure, moving materials in slings or plugs. Features like adaptive air control and pipeline wear materials help manage airflow automatically, reducing blockages for smooth material transfer. The integration of artificial intelligence (AI) enhances performance, making it ideal for cement and mineral processing.

- Vacuum Conveying System: This system employs a vacuum method to draw materials from one location to another, requiring less energy and resulting in low material degradation. It includes dust explosion prevention methods, utilizing explosion venting and inerting systems for flammable materials. Advanced technologies like PLC (programmable logic controller) and HMI (human-machine interface) facilitate remote monitoring, making this system suitable for the chemical and pharmaceutical industries.

- Positive Pressure Conveying System: Used for pushing materials under high pressure through pipelines, this system is effective for long-distance transport. Hybrid systems combine positive pressure with vacuum technologies to handle larger materials and increase productivity. This system operates under high pressure and incorporates noise reduction technology to minimize noise pollution, typically used in the plastic industry and renewable energy generation.

Technical Features:

For more clarification about our pneumatic conveying system in India, we have attached a technical sheet below:

| Parameter | Dilute Phase Conveying System | Dense Phase Conveying System | Vacuum Conveying System | Positive Pressure Conveying System |

|---|---|---|---|---|

| Operating Principle | High-velocity air stream to suspend materials | Low-velocity, high-pressure, moving in plugs | Material drawn through negative pressure | Material pushed with positive pressure |

| Flow State | Suspension of particles in airflow | Dense phase plug flow or slug flow | Similar to dilute but using vacuum | Similar to dilute but using positive pressure |

| Material Suitability | Fine, dry, non-abrasive materials | Granular, abrasive, fragile, and cohesive materials | Suitable for fine powders and granules | Suitable for heavy and larger particles |

| Typical Velocity Range | 15-30 m/s | 2-10 m/s | 15-30 m/s | 15-30 m/s |

| Typical Pressure Range | Up to 1 bar (low pressure) | 2-6 bar (high pressure) | Negative pressure (up to -0.5 bar) | Positive pressure (up to 1.5 bar) |

| Air-to-Material Ratio | High (more air, less material) | Low (less air, more material) | Moderate (similar to dilute phase) | High (similar to dilute phase) |

| Energy Consumption | High | Lower | Moderate | High |

| Distance Capability | Suitable for long distances (up to 500m) | Suitable for shorter distances (up to 150m) | Best for short to medium distances (up to 100m) | Suitable for long distances (up to 500m) |

| Material Degradation Risk | High (due to high velocity) | Low (gentler on materials) | Moderate (less impact due to negative pressure) | High (depending on pressure and material) |

Features and Benefits of using our Pneumatic Conveying Systems

- Advanced Pressure Sensing: The new technological sensors in these pneumatic conveying systems enable real-time monitoring and control of system pressure. The latest updated software ensures smoother operations.

- Integrated Safety Features: Advanced sensors and control systems enhance safety standards by detecting potential hazards and taking corrective actions. Emergency stop buttons and pressure monitoring prevent future risks and material damage.

- Advanced Data Analytics: This feature provides real-time data insights on performance and material flow, which is particularly useful in industrial sectors. It helps improve performance and maintain accurate records.

- Energy Efficient Motors: All motors in these pneumatic conveying systems are energy-efficient, consuming less energy than traditional systems. Permanent magnet motors minimize unwanted heat generation, increasing system reliability and motor lifespan.

Applications of Pneumatic Conveying Systems:

As a former pneumatic conveying system suppliers and exporters in India, we are providing a best system which gives extra performance in every industry such as:

- Food Processing Material Transfer

- Pharmaceutical Powder Handling Systems

- Chemical Plant Pneumatic Transport

- Cement Industry Material Conveying

- Plastic Manufacturing Pellet Transfer

- Paper Mill Pneumatic Conveying

- Waste Management Material Handling

- Textile Industry Fiber Transfer

- Recycling Facility Material Sorting

- Energy Plant Fuel Transfer

- Mining Industry Ore Conveying

- Construction Material Transfer Systems

Being the best pneumatic conveying system manufacturers in India, suppliers and exporters in India, we at Rathi Engineering are committed to simplifying the industrial work with the help of our new advanced technological pneumatic conveying system. These are made with pure forms of raw materials such as stainless steel and cast iron, which are more useful for increasing the durability and performance. Contact us today for more information!