Hammer Mill Manufacturers in Nigeria | Rathi Engineering

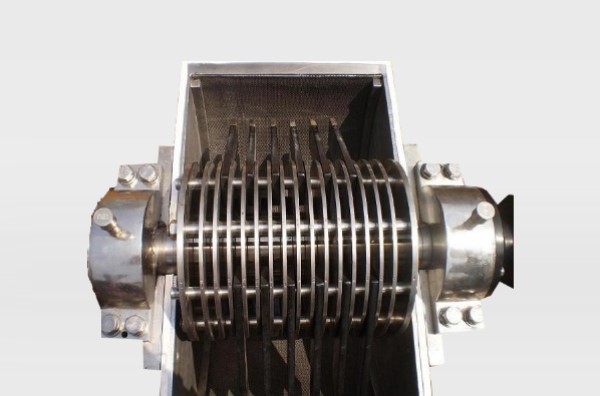

Rathi Engineering, one of the leading hammer mill manufactures, suppliers and exporters in Nigeria, is providing a strong quality hammer mill machine that is made up of a higher strength steel alloy, particularly manganese steel.

The hammers are made with steel and cast iron and applied impactful and greater force for crushing materials such as wood, chips, grain and other metallic or agricultural waste. As the new technology evolves, we have added multiple functions to these machines, such as modular designs, faster screens and hammer changeover mechanisms. Let’s check out its working mechanisms, various features and list of applications where it is highly used!

Multiple types of Hammer Mill Manufacturers, which we offer:

As a former hammer mill suppliers and exporters in Nigeria, we are providing a wide range of types, which helps for increasing the performance in multiple applications. Here we have listed down some types, such as:

- Gravity Discharge Hammer Mill: This type of mill works under the control of gravity, and the material is crushed by high-speed rotating hammers and collected in the grinding chamber. The new technological sensors are attached to this mill, and hammer mills come with variable speed drives for improving the performance of grinding. Mostly, these are used in the agricultural and food and beverage industries.

- Full Circle Screen Hammer Mill: Due to the new technological evolutions, this hammer mill comes with a large screen that covers 360-degree circumference. This technology helps for crushing particles into minute form and monitors the whole process. The advanced feed control systems control the whole mechanism of the mill and increase productivity.

- Industrial Hammer Mill: In this type of hammer mill, we have used a tough and high-quality hammer that is made with cast iron and heavy-duty stainless steel. These are used for handling bulk quantities of materials and performing major tasks. We have used updated sensors and software that gives real-time monitoring of the whole process.

- Pneumatic Discharge Hammer Mill: For getting the finest amount of powder and high-quality grinding materials, we offer our pneumatic discharge hammer mill. The higher air pressure is used for the grinding process instead of gravity. The improved dust control technology in this mill helps enhance filtration systems, and the high quality of the baghouse is used for the collection of grinding materials.

Technical Sheet of our Hammer Mill:

| Specification | Gravity Discharge Hammer Mill | Full Circle Screen Hammer Mill | Industrial Hammer Mill | Pneumatic Discharge Hammer Mill |

|---|---|---|---|---|

| Design | Rectangular design, bottom discharge | Circular screen design, 360° screen coverage | Heavy-duty construction with reinforced steel | Similar to gravity discharge but with pneumatic exhaust system |

| Power Range | 5 – 250 HP | 5 – 200 HP | 10 – 500 HP | 5 – 250 HP |

| Screen Coverage | 180° screen coverage | 360° screen coverage | 180° screen coverage | 180° screen coverage |

| Ideal Materials | Wood chips, grain, biomass, agricultural products | Fine powders, grains, spices, grasses | Fiberglass, metal shavings, plastics, e-waste | Light materials, wood chips, paper, spices |

| Feed Size | Medium to large chunks | Smaller feed materials | Larger feed materials, variable size | Small to medium chunks |

| Airflow Requirement | No air assist needed | Moderate airflow for material movement | None | Requires an external air system for efficient operation |

| Typical Rotor Speed | 1,800 – 3,600 RPM | 3,000 – 3,600 RPM | 1,800 – 2,500 RPM | 1,800 – 3,600 RPM |

| Screen Opening Sizes | 1/16" to 2" | 1/8" to 1" | 1/16" to 6" | 1/16" to 1" |

| Material Discharge | By gravity | Through airflow via 360° screen | By gravity or conveyor | Pneumatically assisted for faster discharge |

| Capacity | 1 to 50 tons per hour | 1 to 25 tons per hour | 5 to 100 tons per hour | 1 to 50 tons per hour |

| Noise Level | Medium | Low to medium | High | Medium |

Features of our Hammer Mill:

As a former hammer mill suppliers and exporters in Nigeria, our hammer mill comes with multiple types of features that help increase performance. Here we have listed down some:

- Versatile Screen Options: All types of hammer mills contain big screen options, which help for tracking and live monitoring of processes. We have added multiple types of controls, and this screen is more useful for controlling and improves ease of use for workers.

- Adjustable Components: The overall components of this machine can be easily operated and controlled by the single controlling unit and operated on a touchscreen. The full-circle design of this hammer mill is attached with fewer components, and these rotor motors are also able to control in all ways.

- Wide Range of Applications: Due to the new technological updates and high quality of raw materials, these hammer mills are highly used in multiple types of industries, such as agricultural processes for processing biological waste, the food and beverage industry for grinding processes, and the industrial sector for handling bulk amounts of materials.

- Energy Efficient: We have specially focused on the energy-saving operations area and used new technological motors that take less energy for processing. The new sensors also detect the materials and use power according to the grinding process. This whole system helps contribute to a greener environment and also benefits cost-cutting.

Applications of Hammer Mill:

Being best hammer mill manufacturers and suppliers in Nigeria, our hammer mill is highly used in multiple types of industries such as:

- Grinding grains into animal feed particles

- Size reduction of hard mineral ores

- Processing biomass for biofuel production

- Shredding scrap wood for recycling purposes

- Pulverizing spices and herbs for seasoning

- Breaking down pharmaceutical raw materials

- Crushing and recycling construction demolition waste

- Refining organic materials for composting use

As one of the prominent hammer mill manufacturers, suppliers and exporters in Nigeria, we, Rathi Engineering, are offering the best quality of hammer mills, which are made with pure quality raw materials and technological updates. This hammer mill usually works with gravitational force and takes less energy to operate. The outer body is deeply coated with multiple coating methods, where it can easily be applied in the outer environment. For more information, contact us today!