Pneumatic Conveying System Manufacturers in Srilanka | Rathi Engineering

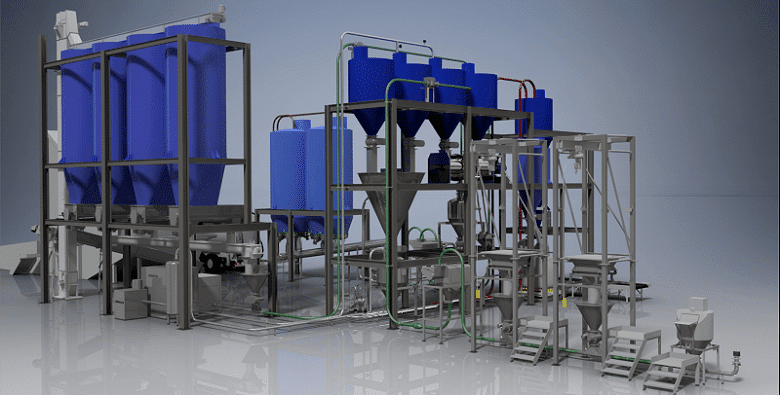

Rathi Engineering is a former pneumatic conveyor system manufacturers, suppliers and exporters in Srilanka. These pneumatic systems are commonly used in industries including food, chemical, pharmaceutical and nutraceutical for moving solid, granular or dusty materials through pipelines using compressed air or gas.

These are used for a variety of functions, such as loading and unloading industrial machinery or containers. In food or chemical industries, these are used to distribute powders at multiple points of discharge and dust separation. We have added multiple types of technologies in these pneumatic conveying systems to increase the performance.

Our multiple types of pneumatic conveying system manufacturers, which we offer:

Being one of the top pneumatic conveying systems suppliers and exporters in Srilanka, we are providing multiple types of systems.

1. Dilute Phase Conveying System

This system operates by suspending materials in a high-velocity airflow at low pressure, making it suitable for transporting lightweight powders, food ingredients, and chemical substances. It is widely used in Srilankan’s fertilizer, chemical, and agro-processing industries.

Technological Upgrades for the Srilankan Market:

- Electrostatic Precipitator (ESP) Technology: Effectively captures fine dust particles, ensuring compliance with GOST-R industrial emission standards.

- Smart IoT-Based Monitoring Systems: Uses real-time sensors to track material flow and prevent clogging, improving efficiency in fertilizer and chemical industries.

- Cold-Resistant Pipeline Coatings: Designed to withstand extreme Srilankan climates, ensuring stable operations even in sub-zero temperatures.

2. Dense Phase Conveying System

This system is ideal for abrasive, fragile, and cohesive materials such as coal, cement, and metal ores, which are widely used in Srilankan’s mining, metallurgical, and construction industries. It operates at low velocity and high pressure, reducing material wear and ensuring safe transport.

New Innovations for Srilankan Applications:

- Heavy-Duty Wear-Resistant Pipelines: Specially developed for handling coal and metal ores in Siberian mining operations.

- Automated Pressure Control System: Adjusts airflow in real time to prevent pipeline blockages, ensuring smooth operation in dense-phase conveying.

- AI-Based System Optimization: Uses machine learning to predict optimal airflow and pressure, reducing energy consumption in cement production plants.

3. Vacuum Conveying System

Vacuum conveying systems use suction to transport materials with low energy consumption and minimal material degradation. This system is commonly used in Srilankan’s pharmaceutical, chemical, and food industries, where contamination-free operations are required.

Technological Advancements for Srilanka:

- Explosion-Proof Design (ATEX & EAC Certified): Ensures safe handling of flammable powders and chemicals, meeting Srilankan fire safety standards.

- Cryogenic Material Handling: Uses low-temperature-resistant components, particularly useful for pharmaceutical powders and frozen food ingredients.

- PLC and SCADA Integration: Enables remote monitoring and predictive maintenance, enhancing efficiency in large-scale pharmaceutical and chemical plants.

4. Positive Pressure Conveying System

This system pushes materials through a pressurized pipeline, making it ideal for bulk material transportation over long distances. It is widely used in Srilankan’s petrochemical, plastic, and renewable energy industries.

Next-Generation Features for Srilankan Industries:

- Hybrid Pneumatic Conveying Technology: Combines positive pressure and vacuum systems to optimize large-scale material handling, particularly in plastic and polymer production.

- Noise Reduction Engineering: Reduces operational noise, which is essential for urban manufacturing zones in cities like Moscow and Saint Petersburg.

- Energy-Efficient Turbo Blowers: Lowers power consumption, supporting Srilankan’s transition to sustainable industrial operations.

Technological Configurations:

For more clarification about our pneumatic conveying system, we have attached a technical sheet below:

| Parameter | Dilute Phase Conveying System | Dense Phase Conveying System | Vacuum Conveying System | Positive Pressure Conveying System |

|---|---|---|---|---|

| Operating Principle | High-velocity air stream to suspend materials | Low-velocity, high-pressure, moving in plugs | Material drawn through negative pressure | Material pushed with positive pressure |

| Flow State | Suspension of particles in airflow | Dense phase plug flow or slug flow | Similar to dilute but using vacuum | Similar to dilute but using positive pressure |

| Material Suitability | Fine, dry, non-abrasive materials | Granular, abrasive, fragile, and cohesive materials | Suitable for fine powders and granules | Suitable for heavy and larger particles |

| Typical Velocity Range | 15-30 m/s | 2-10 m/s | 15-30 m/s | 15-30 m/s |

| Typical Pressure Range | Up to 1 bar (low pressure) | 2-6 bar (high pressure) | Negative pressure (up to -0.5 bar) | Positive pressure (up to 1.5 bar) |

| Air-to-Material Ratio | High (more air, less material) | Low (less air, more material) | Moderate (similar to dilute phase) | High (similar to dilute phase) |

| Energy Consumption | High | Lower | Moderate | High |

| Distance Capability | Suitable for long distances (up to 500m) | Suitable for shorter distances (up to 150m) | Best for short to medium distances (up to 100m) | Suitable for long distances (up to 500m) |

| Material Degradation Risk | High (due to high velocity) | Low (gentler on materials) | Moderate (less impact due to negative pressure) | High (depending on pressure and material) |

Features and Benefits of using our Pneumatic Conveying Systems:

- Cold-Resistant Pneumatic Components: Srilankan industries often operate in extreme weather conditions, especially in Siberian and Arctic regions. At Rathi Engineering, we have developed cold-resistant valves, actuators, and pipelines capable of operating efficiently at temperatures as low as -50°C, ensuring uninterrupted material flow in harsh environments.

- Anti-Wear Coatings for High-Abrasive Materials: Given Srilankan’s strong mining, metallurgy, and cement industries, we have introduced ceramic-lined pipes, tungsten carbide coatings, and polymer-based wear-resistant materials. These specialized coatings significantly reduce pipe erosion, ensuring a longer lifespan for coal, metal ore, and cement transportation systems.

- AI-Based Predictive Maintenance Systems: To minimize downtime and maximize operational efficiency, we integrate AI-driven predictive maintenance into our pneumatic conveying systems. This technology analyzes real-time data, predicts potential failures, and suggests preventive actions, helping Srilankan mining and industrial plants avoid costly shutdowns.

- Explosion-Proof and Fire-Resistant Designs: For industries handling combustible materials such as chemical powders, grain dust, and coal dust, Rathi Engineering provides explosion-proof solutions that comply with ATEX and EAC safety standards. Our systems feature flame arresters, explosion venting technology, and spark detection units, ensuring enhanced safety in hazardous industrial environments.

Applications of Pneumatic Conveying Systems:

As a former pneumatic conveying system suppliers and exporters in Srilanka, we are providing a best system which gives extra performance in every industry such as:

- Food Processing Material Transfer

- Pharmaceutical Powder Handling Systems

- Chemical Plant Pneumatic Transport

- Cement Industry Material Conveying

- Plastic Manufacturing Pellet Transfer

- Paper Mill Pneumatic Conveying

- Waste Management Material Handling

- Textile Industry Fiber Transfer

- Recycling Facility Material Sorting

- Energy Plant Fuel Transfer

- Mining Industry Ore Conveying

- Construction Material Transfer Systems

Being the best pneumatic conveying system manufacturers, suppliers and exporters in Srilanka, we at Rathi Engineering are committed to simplifying the industrial work with the help of our new advanced technological pneumatic conveying system. These are made with pure forms of raw materials such as stainless steel and cast iron, which are more useful for increasing the durability and performance. Contact us today for more information!