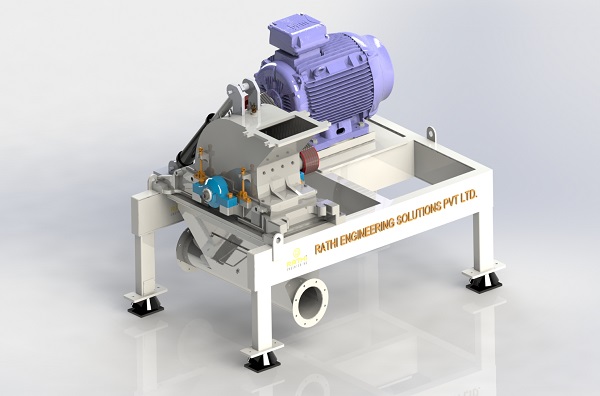

Pulverizer Machine Manufacturers in Hyderabad– Rathi Engineering

Rathi Engineering, leading pulverizer machine manufacturers, suppliers and exporters in Hyderabad, offers one of the best pulverizer machines, which are basically used for grinding the materials into fine particles or powders. These are formally used in the food and beverage industry, coal and powder plants, and pharmaceutical industry.

This machine can be able to work in multiple forms, such as pulverizing, crushing and grinding a wide variety of materials to varying finesses. The integration of automation and IoT helps increase the performance and this machine can be handled with remote operations. Let’s find out its multiple types, applications and features one by one!

Our multiple types of Pulverizer Machine Manufacturers in Hyderabad:

As a leading pulverizer machine supplier and exporter in Hyderabad, all our pulverizer machines are made with new technological updates for increasing performance in every industry. Here we have briefly mentioned below:

- Industrial Pulverizer Machine: These machines are largely used in multiple applications such as coal, minerals, chemicals and plastics and are built with heavy-duty materials such as stainless steel, cast iron and aluminum for extra finishing. These modern pulverizer machines are connected with IoT-based smart control systems for live monitoring of machine performance and operating tasks. This is helpful for ease of use and managing productivity daily.

- Commercial Pulverizer: Our commercial pulverizers are commonly used in medium- to large-scale industries for managing the overall performance and can process multiple types of materials that are used in areas such as food processing plants and spice manufacturing. These machines can handle bulk amounts of materials such as grains, spices, herbs and other food products. It comes compact, and its modular components can quickly be repaired and upgraded.

- Chili and Spices Pulverizer: For handling the materials such as red chilli, turmeric, cumin, coriander and other similar types of ingredients. This machine is highly used in the food spice industry for producing a variety of foods. The new cryogenic technology has been enabled in our pulverizer machine, which keeps the materials cool before grinding and is able to keep the essential elements of spices such as flavor, aroma and color.

- SS Pulverizer Machine: We have used high quality steel while manufacturing these SS (Stainless steel pulverizer machines), where hygiene is the topmost priority. This machine is commonly used to pulverize grains, pulses, spices, herbs and other kinds of food materials. The stainless steel is easy to clean and handle. The high-quality grinding blades are used for better grinding, which has great sharpening quality. These pulverizer machines are installed with low-noise and vibration motors for quiet operation.

Technical Features:

We have attached below a technical sheet which gives you detailed technical information about our pulverizer machine:

| Parameter | Industrial Pulverizer Machine | Commercial Pulverizer | Chili and Spices Pulverizer | SS Pulverizer Machine |

|---|---|---|---|---|

| Material Handling Capacity | 200 kg/hr to 5000 kg/hr | 50 kg/hr to 500 kg/hr | 30 kg/hr to 200 kg/hr | 20 kg/hr to 300 kg/hr |

| Motor Power | 10 HP to 100 HP | 2 HP to 25 HP | 2 HP to 30 HP | 3 HP to 15 HP |

| Grinding Mechanism | Hammer mill, impact, and shear grinding | Impact and blade grinding | Pin mill or hammer mill with fine blades | Blade and impact grinding |

| Material Compatibility | Coal, minerals, chemicals, plastics | Grains, pulses, spices, herbs | Red chili, turmeric, cumin, coriander | Grains, spices, pulses, herbs, food materials |

| Construction Material | Heavy-duty steel or alloy steel | Mild steel or stainless steel | Stainless steel | 100% food-grade stainless steel |

| Feeding System | Automatic and continuous feeding with vibratory feeder options | Manual or automatic hopper feeding | Manual feeding, automatic feeders available | Manual feeding or automatic hopper |

| Output Fineness | 200 mesh to 400 mesh | 100 mesh to 300 mesh | 80 mesh to 300 mesh | 50 mesh to 200 mesh |

| Cooling Mechanism | Air or water-cooled systems | Air-cooled | Optional cryogenic cooling (for sensitive spices) | Air-cooled |

| Energy Efficiency | High-efficiency motors, Variable Frequency Drive (VFD) | Standard motors, optional VFD for energy efficiency | High-efficiency motors, VFD available for adjustable speed | High-efficiency motors with VFD |

| Control System | PLC-based automated control, IoT-enabled | Manual or semi-automated operation | Manual or PLC-based automated control | Semi-automated or fully automated control |

| Noise Level | 85 to 95 dB | 80 to 90 dB | 75 to 85 dB | 70 to 85 dB |

Multiple types of benefits and features of our Pulverizer Machine:

Being a best pulverizer machine suppliers and exporters in Hyderabad, our all machines are made with advanced technology which gives you multiple benefits such as:

- Higher grinding efficiency: The high speed of impact mills and blades is used in these pulverizer machines for effective grinding and making materials into fine powders. Due to the integration of IoT, you can monitor the overall process for live tracking and control the overall process.

- Energy efficient: We have used new technological motors in these machines, which automatically detect the capacity of the materials and use the power. The smart management system uses the energy as per the required product and automatically adjusts the power consumption.

- Increased Automation and Control: Due to automation, reduces manual labor and increases the accuracy of material handling. The AI-driven control system and IoT integration give real-time performance adjustment of the overall machine and reduce maintenance costs.

- Raw Materials: We have used high-quality raw materials in our pulverizer machines, such as aluminum, stainless steel and cast iron, to improve durability and performance. The high quality of stainless steel gives extra smoothness while operating and prevents any stickiness.

Applications of our Pulverizer Machine:

As a dominant pulverizer machine suppliers and exporters in Hyderabad, our all machines are highly used in multiple industries due to its new technological Upgradation; here we have listed down some applications:

- Grinding coal for thermal power plants

- Pulverizing plastic materials for recycling processes

- Crushing and grinding chemicals for manufacturing

- Powdering minerals and ores in mining industry

- Grinding grains and spices for food production

- Processing fertilizers and pesticides in agriculture

- Reducing size of rubber for recycling

- Pulverizing metals and alloys for metallurgy

- Making fine powders for pharmaceutical applications

- Breaking down biomass for biofuel production

As prominent pulverizer machine manufacturers, suppliers and exporters in Hyderabad, we at Rathi Engineering are providing one of the best pulverizer machines with new technological updates such as cryogenic methods and PLC systems. We have used high-quality raw materials such as stainless steel and cast iron for improving its durability. For more information, contact us today!