Rotary Airlock Valves Manufacturers in Hyderabad| Rathi Engineering

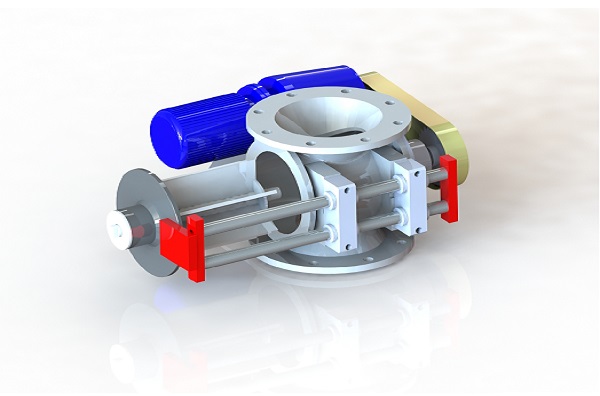

Rathi Engineering, one of the best rotary air valve manufacturers, suppliers and exporters in Hyderabad, is offering new technological and high-quality rotary air valves that are made with strong-quality raw materials such as carbon steel, cast iron and aluminum for more finishing. We have used stainless steel, particularly 304 and 316 grades.

This rotatory air valve is particularly used for handling bulk and dry solid materials such as granules, crystals and powders. These are essential for keeping material handling and pneumatic conveying systems efficient and reliable. We have included new technological updates in all types of rotary air valves, which help increase performance and productivity.

Our multiple types of Rotary Air Valve Manufacturers, which we offer:

Being one of the best rotary air valve suppliers and exporters in Hyderabad, we are offering a wide range of types, and each is made with high-quality materials. Here we have briefly mentioned some types, such as:

- Drop-Through Rotary Air Valve: Commonly used for handling bulk and dry materials, this valve features a direct-drop-through design. It efficiently manages various materials such as dry powders, granules, and other bulk substances. Smart sensors enable live monitoring of temperature, pressure, and overall process performance, while wear-resisting coatings, including ceramic and tungsten carbide, enhance durability.

- Blow-Through Rotary Air Valve: Typically utilized in the food and beverage industry for precise grinding processes, this valve includes a secondary air injection port that helps expel materials from the rotor, improving pneumatic conveying efficiency. A self-cleaning mechanism effectively removes sticky materials using minimal water, preventing blockages.

- Dust Tight Rotary Air Valve: Designed to prevent dust and fine particle contamination, this valve incorporates technologically advanced sealed bearings and airlock mechanisms. It is crucial in the chemical, pharmaceutical, and food processing industries. The valve features explosion venting and suppression technologies to handle dust in compliance with ATEX and NFPA standards.

- High-pressure Rotary Air Valve: Suitable for the industrial sector, this valve operates under high-pressure conditions and is used for handling large bulk materials. Advanced flow control systems provide real-time monitoring and adjustments, while PLC control facilitates pressure feedback updates. Its robust design makes it ideal for industries such as cement, mining, and power plants.

Technical Specifications:

For more understanding about our rotary air valve, we have mentioned below a technical sheet which helps for increasing performance:

| Specification | Drop-Through Rotary Air Valve | Blow-Through Rotary Air Valve | Dust Tight Rotary Air Valve | High Pressure Rotary Air Valve |

|---|---|---|---|---|

| Material of Construction | Cast iron, stainless steel | Cast iron, stainless steel | Stainless steel, aluminum | Heavy-duty stainless steel, carbon steel |

| Operating Pressure | 0.5 to 1 bar | Up to 1.5 bar | 0.5 to 1 bar | 2 to 4 bar |

| Rotor Design | Open rotor with straight vanes | Closed rotor with blow-through channels | Closed rotor, minimal gaps | Sealed rotor with precision machining |

| Rotor Speed | 10-30 RPM | 15-50 RPM | 10-30 RPM | 5-15 RPM |

| Capacity | 0.5 to 20 m³/h | 1 to 30 m³/h | 0.5 to 20 m³/h | 0.2 to 15 m³/h |

| Operating Temperature | -20°C to +80°C | -20°C to +100°C | -20°C to +80°C | -20°C to +150°C |

| Seal Type | Lip seals or O-rings | Shaft seals with packing glands | High-grade mechanical seals, dust-proof | Specially designed pressure seals |

| Drive Options | Direct coupled, chain, or belt driven | Direct coupled, chain, or belt driven | Direct coupled, motorized | Direct coupled, heavy-duty gear drive |

| Air Leakage | Low | Moderate | Minimal | Very low due to pressure-tight design |

| Explosion Protection | Optional ATEX certification | Optional ATEX certification | ATEX certification required for dusty environments | Mandatory ATEX certification |

| Industries | Food, pharmaceutical, plastics | Food, chemical, cement, plastics | Chemical, food, pharmaceutical | Cement, chemical, mineral, energy sectors |

Some unique features and benefits of using our Rotary Air Value:

As a former rotary air value suppliers and exporters in Hyderabad, our all types of rotary air valves are manufactured with high quality of materials and give multiple benefits such as:

- Smart Sensors: We have used new technological smart sensors and software for increasing the performance of the rotary air valve. It allows for the real-time monitoring of all processes, such as temperature monitoring, pressure rate, and operational conditions. The software can store data and give feedback according to it.

- Improved Seal Technology: To prevent any kind of contamination, such as dust or fine particles, we have improved the seal quality of our rotary air valve. Due to their technology, these are highly used in the food and beverage industry and pharmaceutical industry. We have used self-adjusting seals, which can automatically adjust the seal and maintain effectiveness over time.

- Improved Rotor Design: The aerodynamic design of the blades and machine helps for effective grinding, improves airflow, minimizes turbulence and enhances the overall performance of the machine. For less contamination, we have included a self-cleaning mechanism in this rotary air valve, which can easily remove any sticky materials.

- Noise Reduction Technologies: For quiet operation while grinding, our all-rotary air valve comes with noise reduction technologies and is equipped with acoustic insulation. The new modern design of our machine helps reduce vibrations and gives quieter and smoother operation.

Applications of our Rotary Air Valve:

As a former rotary air valve suppliers and exporters in Hyderabad, our all types of rotary air valve are used in multiple industries such as:

- Pneumatic conveying systems for bulk materials handling

- Discharging materials from hoppers or silos

- Metering and feeding powdered or granular products

- Dust collection systems for pollution control

- Airlock mechanism for maintaining system pressure

- Handling of abrasive or corrosive materials

- Fuel feeding systems for biomass boilers

- Volumetric feeding of chemicals in process industries

- Regulating flow in pneumatic conveying pipelines

- Sealing off systems to prevent air leakage

Being one of the best rotary air valve manufacturers, suppliers and exporters in Hyderabad, we at Rathi Engineering offer one of the best rotary air valves made with new technological updates and gives higher performance. The high-quality raw materials used in these valves, such as stainless steel and cast iron, for improving the outer body of rotary air valves. Due to these all-advanced mechanisms, they are highly used in multiple industries. Contact us today for more information!