Turmeric Grinding Machine Manufacturers in Srilanka | Rathi Engineering

Rathi Engineering, one of the best turmeric grinding machine manufacturers, suppliers and exporters in Srilanka, provides the best turmeric powder maker which is primarily used for reducing turmeric into a fine powder. These are basically used for multiple purposes, such as grinding turmeric, masala herbs and other materials into fine powdered products.

The new cryogenic technology is used to get higher results in taste, flavor and aroma. We have used high-quality raw materials in these machines, such as galvanized stainless steel in the outside machine and hardened and coated steel from the inside to reduce contamination. Let’s discover its multiple types, its features and its applications one by one!

Our multiple types of Turmeric Grinding Machine Manufacturers:

As a dominant Turmeric grinding machine supplier and exporter in Srilanka, we offer a wide range of turmeric grinding machines that can be used in multiple areas to increase performance. Here we have listed some points below:

- Hammer Mill Grinder: For handling bulk amounts of materials, these hammer mill grinders are highly used with new technological updates. These hammers are made with hard-quality stainless steel with high-speed rotating hammers. To reduce the heat while operating on the major task and preserving the essential oil, we have used airflow technology and an automated feed system for efficient handling.

- Pin Mill: The high speed of rotating pins is used in these machines for converting turmeric into pure powders. These machines can handle any kind of bulk materials and convert them into the finest powders because multiple types of sharpened blades are connected to these machines. Cryogenic grinding is used in these machines for cooling the materials while operating under continuous tasks and preserving the material.

- Ball Mill: These machines are most commonly used in industrial areas where the rotating cylinders are attached and filled with grinding media like cylindrical balls. It creates a pure amount of powder due to the friction of cylindrical balls. We have used a new technology in these machines, such as closed-circuit with cyclone separation, where it automatically separates the fine powder from coarser particles for getting more uniform output.

- Jet Mill: These machines are mostly used for saving energy and getting higher quality haldi powder from utilizing high-speed jets that are connected to these machines and rotating at higher speeds. Due to this mechanism, the particles collide with each other and form the finest powder. Our self-cleaning technology helps prevent the buildup of turmeric powder in the grinding chamber and improves efficiency.

Technical Features:

For increasing the performance, we have included a detailed technical sheet about our turmeric grinding machine such as:

| Specifications | Hammer Mill Grinder | Pin Mill | Ball Mill | Jet Mill (Air Classifier Mill) |

|---|---|---|---|---|

| Grinding Mechanism | Impact and cutting via rotating hammers | High-speed rotating pins | Impact and friction using grinding media | Particle collision via high-speed air jets |

| Particle Size Range | 50 - 500 microns | 10 - 200 microns | Sub-micron to 100 microns | 1 - 50 microns |

| Capacity (kg/h) | 100 - 2,000 kg/h | 50 - 1,000 kg/h | 50 - 500 kg/h | 10 - 300 kg/h |

| Energy Consumption | Medium (20-50 kWh/ton) | Medium to high (25-60 kWh/ton) | High (50-80 kWh/ton) | Low (10-30 kWh/ton) |

| Heat Generation | Medium | Low | High | Minimal |

| Operating Temperature | Ambient | Ambient or cryogenic | Elevated (due to friction) | Ambient or cryogenic |

| Fineness Control | Adjustable by changing screen size | Controlled by rotor speed and pin configuration | Variable via grinding media size and time | Fully automated with air classifier |

| Automation Level | Semi-automatic with manual feed adjustment | Fully automatic with feed and speed control | Semi-automatic (intelligent control for fine-tuning) | Fully automatic with touchscreen interface |

| Cooling System | Optional cooling jackets | Cryogenic cooling | No dedicated cooling | Built-in air cooling or optional cryogenic cooling |

| Wear-Resistant Components | High-durability hammers and plates | Replaceable pins and stator plates | Ceramic or steel grinding media | Wear-resistant liners in grinding chamber |

| Noise Level | 75 - 90 dB | 70 - 85 dB | 85 - 100 dB | 60 - 75 dB |

Unique Features and Benefits of Our Haldi Grinding Machine:

As former turmeric grinding machine suppliers and exporters in Srilanka, we have added multiple types of advanced features in our machine, which gives higher performance in every unit:

Cryogenic Grinding Technology:

To preserve the natural color, aroma, and essential oils of turmeric, we integrate cryogenic grinding technology. By using liquid nitrogen, our machines maintain an ultra-low temperature, reducing thermal degradation and enhancing product quality.

2. Multi-Stage Precision Grinding

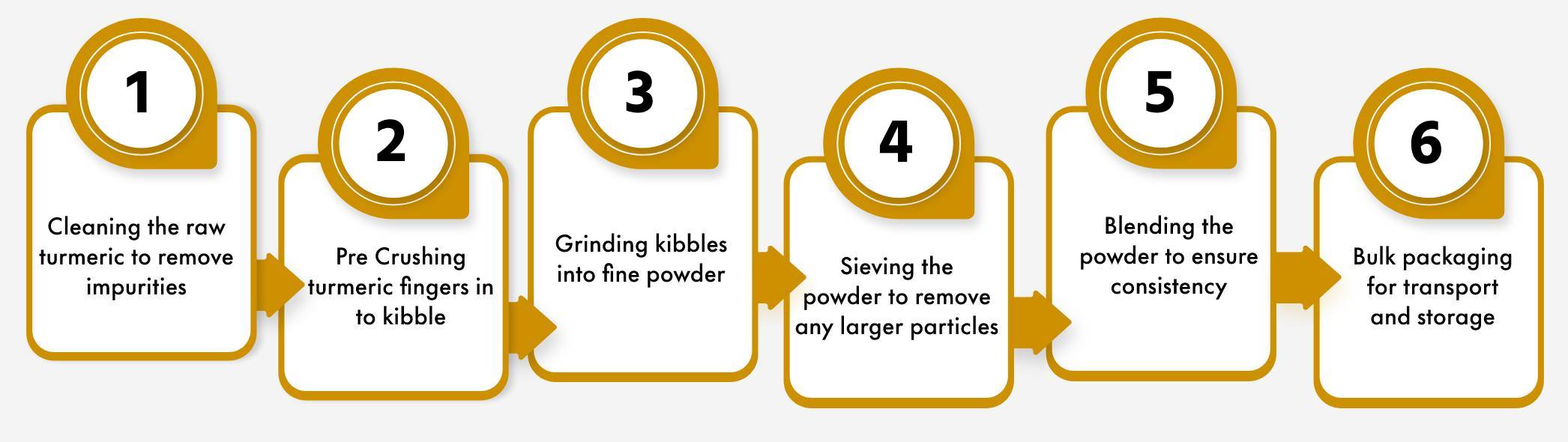

Our machines utilize a three-stage grinding system:

- Coarse grinding for breaking down raw turmeric.

- Fine grinding for consistent texture.

- Ultra-fine grinding to achieve micron or nano-level fineness.

This ensures a uniform particle size with minimal wastage, making it ideal for pharmaceutical, food, and cosmetic industries.

Vibration-Free Structure & Noise Reduction

With an advanced shock-absorption mechanism, our machines operate with minimal vibration and reduced noise levels. This results in a smoother operation and a safer working environment in industrial settings.

4. High-Precision Magnetic Separator

To eliminate metallic impurities, we incorporate powerful magnetic separators that remove ferrous and non-ferrous contaminants. This ensures the purest turmeric powder, meeting strict industry standards.

Applications of our Turmeric Grinding Machines:

AAs prominent Turmeric grinding machine manufacturers and suppliers in Srilanka, our all grinding machines are highly used in multiple applications such as:

- Turmeric powder production for culinary use

- Spice processing in food industries

- Ayurvedic and herbal medicine formulation

- Turmeric extraction for cosmetic ingredients

- Bulk turmeric grinding for commercial supply

- Preparation of organic turmeric health supplements

- Processing turmeric for ready-to-use spices

- Turmeric grinding for packaged spice blends

- Turmeric grinding for food seasoning manufacturing

- Grinding turmeric for export-quality spice production

Being one of the top turmeric grinding machine manufacturers, suppliers and exporters in Srilanka, we, Rathi Engineering, are providing a highly technological turmeric grinding machine that can make a pure form of Turmeric powder without any contamination. The pure quality of raw materials is used while manufacturing these machines for increasing durability and performance. For information, contact us today!